Pulley Type Wire Drawing Machine

Maintenance Tips for Pulley Type Wire Drawing Machines A pulley type wire drawing machine is a crucial piece of…

Maintenance Tips for Pulley Type Wire Drawing Machines

A pulley type wire drawing machine is a crucial piece of equipment in the wire manufacturing industry. It is used to pull wire through a series of dies to reduce its diameter and improve its quality. To ensure the smooth operation of a pulley type wire drawing machine, regular maintenance is essential. In this article, we will discuss some maintenance tips to help you keep your machine in top condition.

One of the most important maintenance tasks for a pulley type wire drawing machine is to regularly inspect and lubricate the pulleys. The pulleys are responsible for guiding the wire through the drawing dies, and any wear or damage to them can cause the wire to break or become misaligned. By inspecting the pulleys regularly and lubricating them as needed, you can prevent these issues and ensure the smooth operation of your machine.

Another important maintenance task for a pulley type wire drawing machine is to check and adjust the tension of the wire. Proper tension is crucial for achieving the desired reduction in wire diameter and preventing breakage. By regularly checking and adjusting the tension of the wire, you can ensure that your machine is operating at its optimal level and producing high-quality wire.

In addition to inspecting and lubricating the pulleys and adjusting the wire tension, it is also important to regularly clean the machine and remove any debris or buildup that may be affecting its performance. Dust, dirt, and other contaminants can accumulate on the machine over time and cause it to operate less efficiently. By cleaning the machine regularly, you can prevent these issues and prolong the life of your equipment.

It is also important to regularly inspect the drawing dies and replace them as needed. The drawing dies are responsible for reducing the diameter of the wire as it passes through the machine, and any wear or damage to them can affect the quality of the finished wire. By inspecting the drawing dies regularly and replacing them when necessary, you can ensure that your machine is producing high-quality wire consistently.

In addition to these maintenance tasks, it is also important to follow the manufacturer’s guidelines for operating and maintaining your pulley type wire drawing machine. The manufacturer’s guidelines will provide you with specific instructions on how to care for your machine and ensure its optimal performance. By following these guidelines, you can prevent unnecessary wear and damage to your equipment and prolong its lifespan.

In conclusion, regular maintenance is essential for keeping your oto type wire drawing machine in top condition. By inspecting and lubricating the pulleys, adjusting the wire tension, cleaning the machine, inspecting and replacing the drawing dies, and following the manufacturer’s guidelines, you can ensure that your machine is operating at its best and producing high-quality wire consistently. By taking the time to care for your equipment properly, you can avoid costly repairs and downtime and keep your wire manufacturing operation running smoothly.

Comparison of Pulley Type Wire Drawing Machine with Other Types

Wire drawing is a process used in the manufacturing industry to reduce the diameter of a wire by pulling it through a series of dies. This process is essential for producing wires of various sizes and shapes that are used in a wide range of applications, from electrical wiring to fencing. There are several types of wire drawing machines available, each with its own unique features and advantages. In this article, we will focus on the pulley type wire drawing machine and compare it with other types to understand its benefits and limitations.

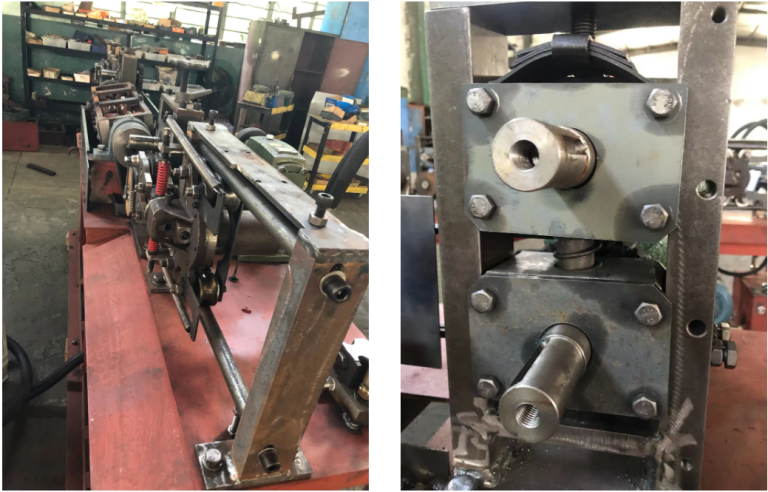

The pulley type wire drawing machine is a popular choice for many manufacturers due to its simplicity and efficiency. This type of machine consists of a series of pulleys that are used to pull the wire through the dies, reducing its diameter in the process. The pulleys are connected to a motor that provides the necessary power to drive the wire through the dies at a controlled speed. One of the main advantages of the pulley type wire drawing machine is its versatility. It can be used to draw wires of various materials, including steel, copper, and aluminum, making it suitable for a wide range of applications.

In comparison to other types of wire drawing machines, such as the drum type and the cone type, the pulley type offers several benefits. One of the key advantages of the pulley type machine is its ability to produce wires with a consistent diameter. The pulleys provide a smooth and continuous pulling action, ensuring that the wire is drawn evenly through the dies. This results in wires that are of high quality and meet the required specifications. Additionally, the pulley type machine is easy to operate and maintain, making it a cost-effective option for many manufacturers.

Another advantage of the pulley type wire drawing machine is its compact size. Unlike drum type machines, which can be bulky and take up a lot of space, pulley type machines are more compact and can be easily integrated into existing production lines. This makes them ideal for manufacturers with limited space or those looking to optimize their production processes. Additionally, the pulley type machine is energy-efficient, requiring less power to operate compared to other types of wire drawing machines.

Despite its many advantages, the pulley type wire drawing machine does have some limitations. One of the main drawbacks of this type of machine is its limited drawing capacity. Pulley type machines are typically used for drawing wires of smaller diameters, making them less suitable for applications that require thicker wires. Additionally, the pulley type machine may not be as fast as other types of wire drawing machines, which can impact production efficiency in some cases.

In conclusion, the pulley type wire drawing machine is a versatile and efficient option for manufacturers looking to produce high-quality wires. Its simplicity, compact size, and energy efficiency make it a popular choice for many applications. While it may have some limitations in terms of drawing capacity and speed, the pulley type machine remains a cost-effective and reliable solution for many manufacturers. By understanding the benefits and limitations of the pulley type wire drawing machine, manufacturers can make informed decisions about the best type of machine for their specific needs.

Benefits of Using Pulley Type Wire Drawing Machine

A pulley type wire drawing machine is a crucial piece of equipment in the wire manufacturing industry. This machine is used to reduce the diameter of a wire by pulling it through a series of dies, resulting in a smoother and more uniform wire. There are several benefits to using a pulley type wire drawing machine, which we will explore in this article.

One of the main advantages of using a pulley type wire drawing machine is its efficiency. This machine is capable of drawing wire at high speeds, allowing for increased productivity and output. The pulley system in the machine helps to reduce friction and resistance, making the drawing process smoother and more efficient. This results in a higher quality wire with consistent diameter and surface finish.

Another benefit of using a pulley type wire drawing machine is its versatility. These machines are capable of drawing wires of various materials, including steel, copper, aluminum, and more. This versatility makes them suitable for a wide range of applications in industries such as construction, automotive, electronics, and more. Additionally, pulley type wire drawing machines can be easily adjusted to accommodate different wire diameters and specifications, making them highly adaptable to different production needs.

In addition to efficiency and versatility, pulley type wire drawing machines also offer cost savings. These machines are designed to operate with minimal energy consumption, reducing overall production costs. The high-speed drawing process also helps to save time and labor, further contributing to cost savings. Additionally, the consistent quality of the wire produced by these machines helps to minimize waste and rework, leading to additional cost savings for manufacturers.

Furthermore, pulley type wire drawing machines are known for their durability and reliability. These machines are built to withstand heavy use and high production demands, ensuring long-term performance and minimal downtime. The pulley system in the machine is designed to withstand high levels of stress and tension, making it a reliable and dependable option for wire manufacturers.

Overall, the benefits of using a pulley type wire drawing machine are clear. From increased efficiency and productivity to versatility and cost savings, these machines offer a range of advantages for wire manufacturers. With their high-speed drawing capabilities, consistent quality output, and durability, pulley type wire drawing machines are an essential tool for any wire manufacturing operation.

In conclusion, pulley type wire drawing machines are a valuable asset for wire manufacturers looking to improve their production processes. With their efficiency, versatility, cost savings, and reliability, these machines offer a range of benefits that can help manufacturers achieve their production goals. Whether producing steel wire for construction or copper wire for electronics, a pulley type wire drawing machine is a reliable and efficient solution for drawing wire with precision and consistency.